Акт исследования физических свойств

Comparison of physical and mechanical properties of various diamond-like coatings

Physical and Mechanical Properties of the Coating | DLC (ta-C) Special Technologies LLC | DLC (a-CH) | Single Crystal Diamond |

Structure | Amorphous Carbon | Amorphous Carbon | Diamond |

Density, g/cm3 | 3.4 - 3.6 | 3.2-3.4 | 3.6 |

Microhardness, HV, GPa | 50-100 | 15 - 40 | 70-100 |

Coefficient of Dry Friction | 0.15-0.08 | 0.1-0.04 | 0.2-0.05 |

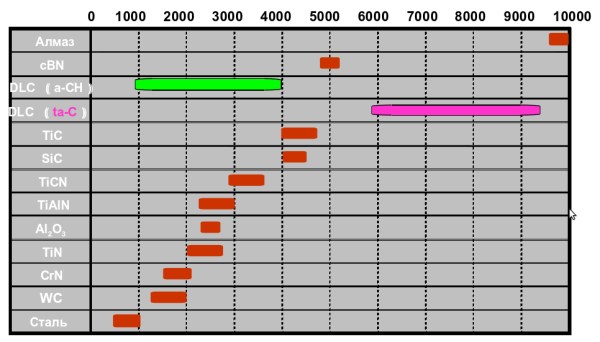

Microhardness of various types of hardening coatings

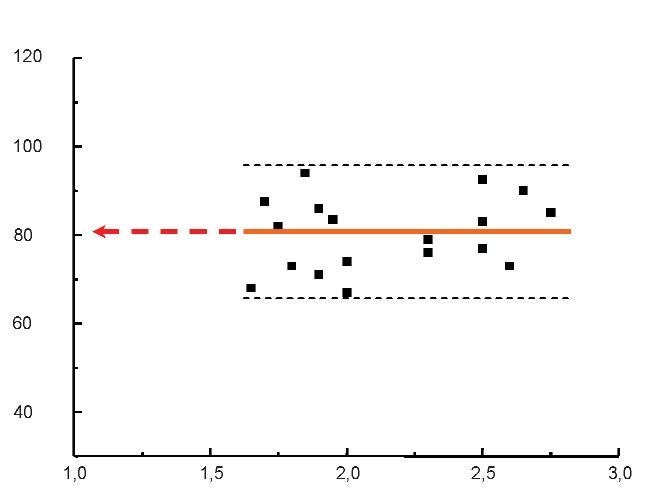

A multilayer coating of complex composition (from a mixture of carbon with metals to pure carbon) has a total thickness of 1.0-1.5 μm and is capable to effectively withstand high mechanical loading. The necessary microhardness value is reached at a thickness of 1.0 μm and above.

Correlation between microhardness and coating thickness of diamond-like coating

Thickness (μm)

Within the technology developed we have also managed to successfully solve the task of obtaining good adhesion that prevented DLC coatings from large-scale introduction in the tool manufacturing industry.

Service life of instruments and tools used for processing ductile metals increases up several times over, from a factor of 5 to one of 20, depending on the type of material being processed.

It is worth mentioning that only application of the method of vacuum pulse sputtering of graphite allows one to reach strength criteria established for metal processing tools in accordance with the national quality standard of the Russian Federation "Diamond-Based Nanocoatings for Cutting Tools"

DLC coatings (ta-C) have a set of unique characteristics:

- Strong adhesion of the deposited films to the surface on which the coating is applied;

- Hardness value of the coating which is comparable to diamond hardness;

- Durability;

- Low coefficient of friction;

- Chemical stability;

- Ecological cleanliness;

- Biological compatibility;

- Transparency in the infra-red band of the spectrum;

- High heat conductivity;

- Corrosion resistance;

- High electrical resistance.